10 Step Estimation Process Sample Checklist

View our 10 Step Estimating Process Checklist. This checklist should be tuned to the individual company’s needs and suggestions.

Parametric modeling plays a pivotal role in advancing project planning, design processes, cost estimation, and strategic decision-making. By employing mathematical models grounded in historical data, it provides precise forecasting for a wide range of industries and applications.

Table of Contents

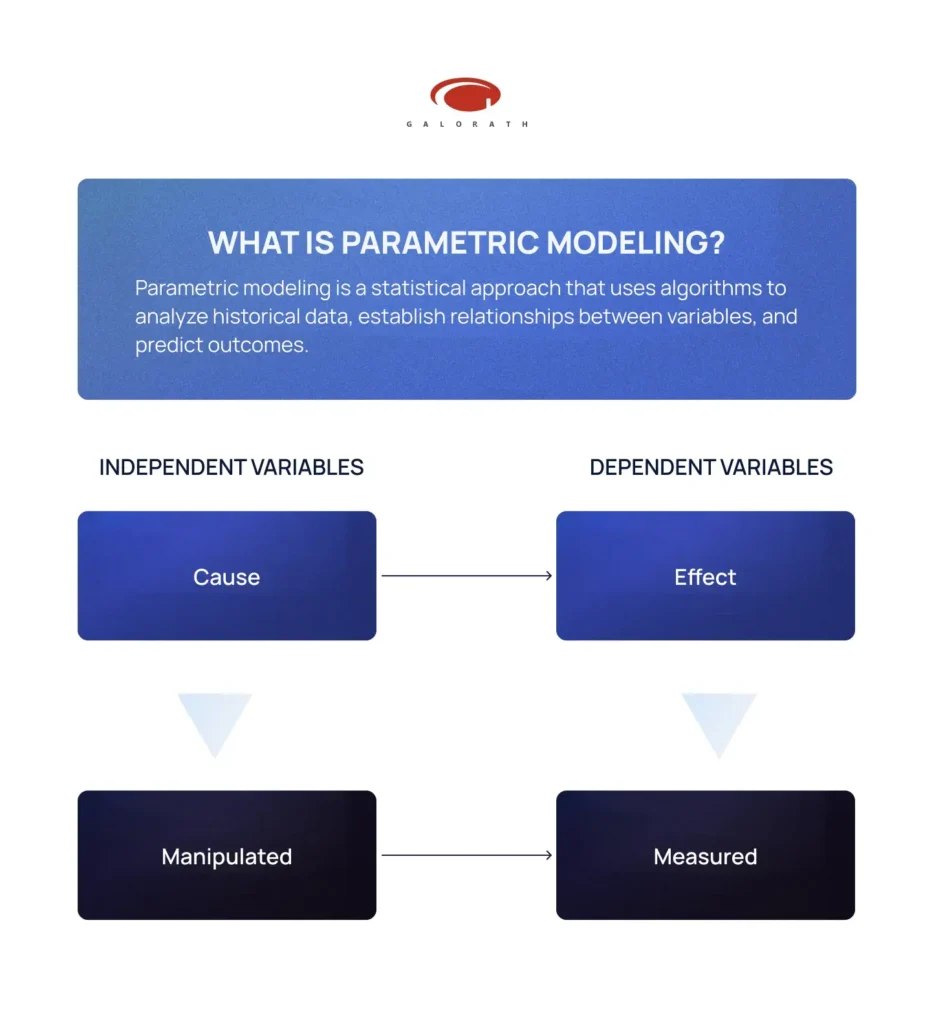

Parametric modeling is a statistical approach that uses algorithms to analyze historical data, establish relationships between variables, and predict outcomes. This method helps with making data-driven decisions by understanding how changes in key variables and parameters affect the final results.

For instance, in project management and cost estimation, variables like labor costs, material prices, or project timelines can impact the overall budget and delivery schedule. By using parametric modeling, our SEER software, can estimate these factors more accurately and reduce the risk of unexpected expenses and delays.

In modern architectural design and 3D modeling, parametric modeling is very significant as it enables architects and designers to set parameters that govern building and model elements. This facilitates dynamic responses to changes in design, geometry, shape, scale, or other design constraints, ultimately leading to optimized architectural and 3D model outcomes.

To understand how parametric modeling works, it’s essential to examine the core components of these models. They typically consist of:

By continuously refining relationships through calibration and computer algorithms, the accuracy of forecasts improves, making parametric models indispensable for complex projects where precision is key.

The Fundamentals of Parametric Models

At its core, parametric modeling relies on data to create a model that forecasts outcomes based on variable inputs. Here’s how the process of creating a model typically works:

This systematic approach of using a parametric model offers a more reliable way to predict outcomes compared to traditional estimation methods, which may rely heavily on assumptions or guesswork.

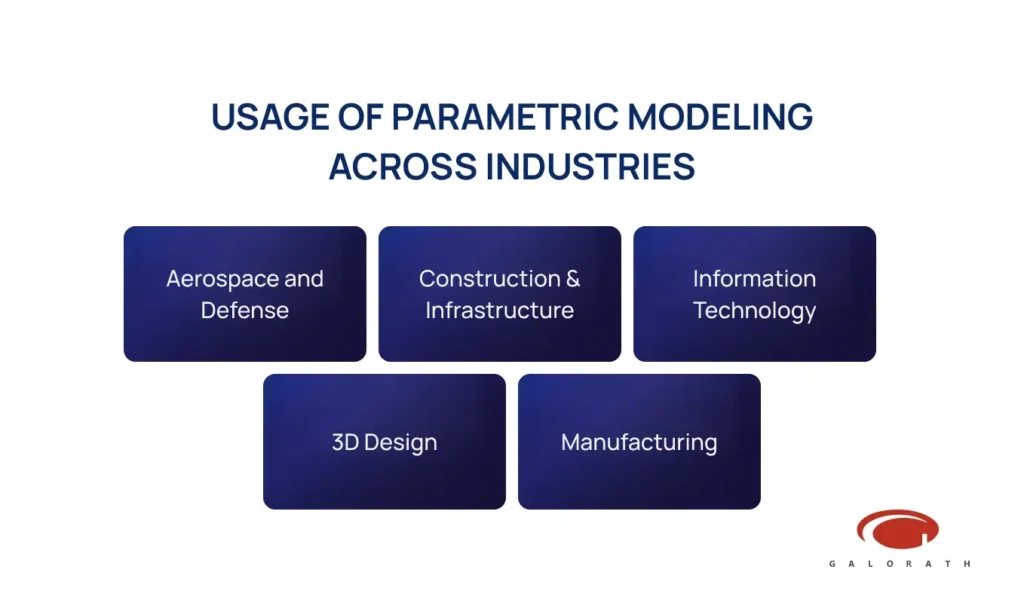

Parametric modeling is widely used across sectors that require precise design estimation, cost estimation, resource allocation, and timeline management. Let’s look at how different industries benefit:

Parametric design is a design technique that uses mathematical equations to create complex relationships between different parts of a design. These relationships, or parameters, allow designers to create and edit geometry designs quickly and efficiently.

For example, changing a single parameter on a solid model, such as the length of a component, can automatically update all related dimensions and features of the entire shape, ensuring that the design remains consistent and accurate.

Parametric design is widely used in fields like architecture, product design, automotive, and aerospace to optimize structures, improve efficiency, and enable rapid customization. It empowers industries to adapt designs swiftly by adjusting parameters, enhancing precision, flexibility, and cost-effectiveness in complex projects.

One of the key principles of parametric design is the concept of design intent. Design intent refers to the underlying logic and rules that dictate how a design should behave. By capturing design intent, parametric modeling software can ensure that changes to one part of a model automatically propagate to other related parts, maintaining the overall integrity of the design.

This ability to create models based on predefined rules makes parametric modeling a powerful tool for designers and engineers.

From mechanical engineering and product design to cost estimation and project planning, parametric modeling is utilized in different software solutions for various purposes that demand adaptability and accuracy.

Parametric modeling software is a type of computer-aided design (CAD) tool that allows designers and engineers to create digital models by defining parameters and relationships between different design elements. These software programs leverage mathematical equations and algorithms to define the connection between different parts of a design, allowing users to models quickly and efficiently.

Some of the most popular parametric modeling software includes Autodesk Inventor, SolidWorks, and CATIA.

For example, Autodesk Inventor provides tools for 3D mechanical design, simulation, and visualization, while SolidWorks offers features for product design, simulation, and data management. CATIA, on the other hand, is known for its advanced capabilities in aerospace and automotive design.

SEER by Galorath is a powerful software suite that applies parametric modeling techniques to streamline cost estimation and project planning. Unlike traditional design software, SEER uses parametric principles to analyze historical data and key parameters, allowing organizations to forecast costs and timelines with a high degree of accuracy.

It enables companies in industries like aerospace, defense, and engineering to generate precise cost estimates for hardware, software, and system engineering projects. By adjusting variables and leveraging predictive models, SEER helps users anticipate project outcomes, optimize budgets, and make informed decisions early in the planning process.

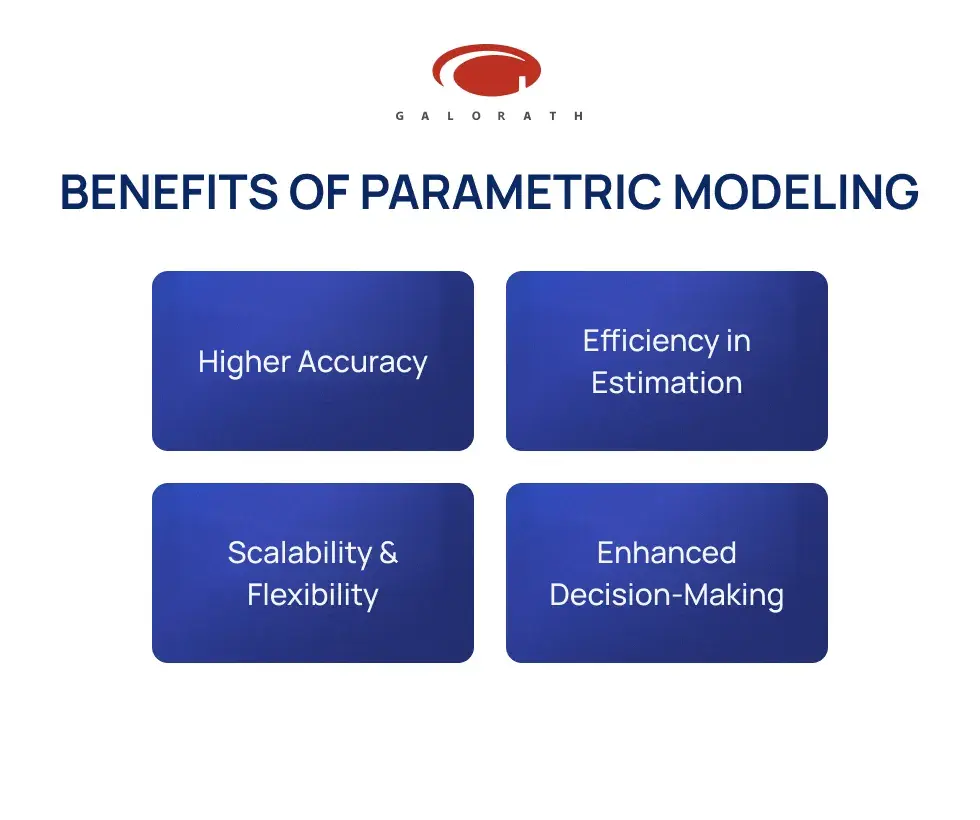

The growing adoption of parametric modeling is driven by its ability to improve project planning and resource management. Here are some of the primary benefits:

Direct modeling is a geometric-based modeling method that provides designers with the flexibility to interact directly with the model’s geometry. It enables quick and intuitive modifications without the need for predefined constraints or parameters, making it particularly advantageous for conceptual designs or organic forms.

Direct modeling approach allows for rapid prototyping and exploration of various design concepts, offering a more hands-on experience in the early stages of the design process.

The primary differences between parametric and direct modeling lie in their approach to design and geometry modification. Parametric modeling captures design intent by defining parameters and constraints, ensuring that any changes automatically update related elements, maintaining the model’s integrity. This makes it ideal for projects requiring precision and automation.

In contrast, direct modeling emphasizes flexibility and speed, allowing easily modified adjustments designer can do without the constraints of predefined parameters. While parametric modeling is suited for detailed engineering and manufacturing processes, a key advantage of direct modeling is in situations where rapid iteration and conceptual exploration are needed.

Parametric and nonparametric modeling are two distinct approaches in statistical analysis and computer aided design. Parametric models rely on predefined parameters and equations to create models, capturing design intent and ensuring that changes automatically update related elements.

In contrast, nonparametric models do not assume a specific form for the model’s distribution, allowing for greater flexibility in capturing complex relationships within data. This approach is beneficial when dealing with data that doesn’t fit traditional parametric assumptions, providing a more adaptable framework for analysis.

While parametric models are efficient for well-defined tasks with clear constraints, nonparametric models offer the versatility needed for exploratory data analysis and situations where the underlying structure of the data is unknown.

To better understand how parametric modeling drives success, let’s explore examples of how leading companies in various sectors have applied these techniques.

While parametric modeling is powerful, there are challenges that organizations need to address to maximize its effectiveness. Here are a few common obstacles and strategies for overcoming them:

Parametric modeling represents a paradigm shift in how industries approach design, cost estimation, and strategic planning. By leveraging data-driven algorithms to identify relationships between variables, it enhances precision, efficiency, and scalability across sectors such as construction, aerospace, software development, and manufacturing.

As organizations increasingly adopt this approach, the focus will shift to overcoming challenges like data accuracy, model complexity, and change management. Those who successfully integrate parametric modeling into their workflows will gain a competitive advantage, driving innovation and optimizing project outcomes in constantly evolving markets.

10 Step Estimation Process Sample Checklist

View our 10 Step Estimating Process Checklist. This checklist should be tuned to the individual company’s needs and suggestions.

Estimating Total Cost of Ownership (TCO)

Find out how you can use Total Cost of Ownership (TCO) model to create an estimate which includes all the costs generated over the useful life of a given application.

Should Cost Analysis

Learn how Should-Cost Analysis can identify savings opportunities and drive cost efficiency in procurement and manufacturing processes.

ROM Estimate: The First Step Towards a Detailed Project Plan

Find out what ROM (rough order of magnitude) estimate is and why is it a crucial element of every project planning cycle.

Software Maintenance Cost

Find out why accurate estimation of software maintenance costs is critical to proper project management, and how it can make up to roughly 75% of the TCO.