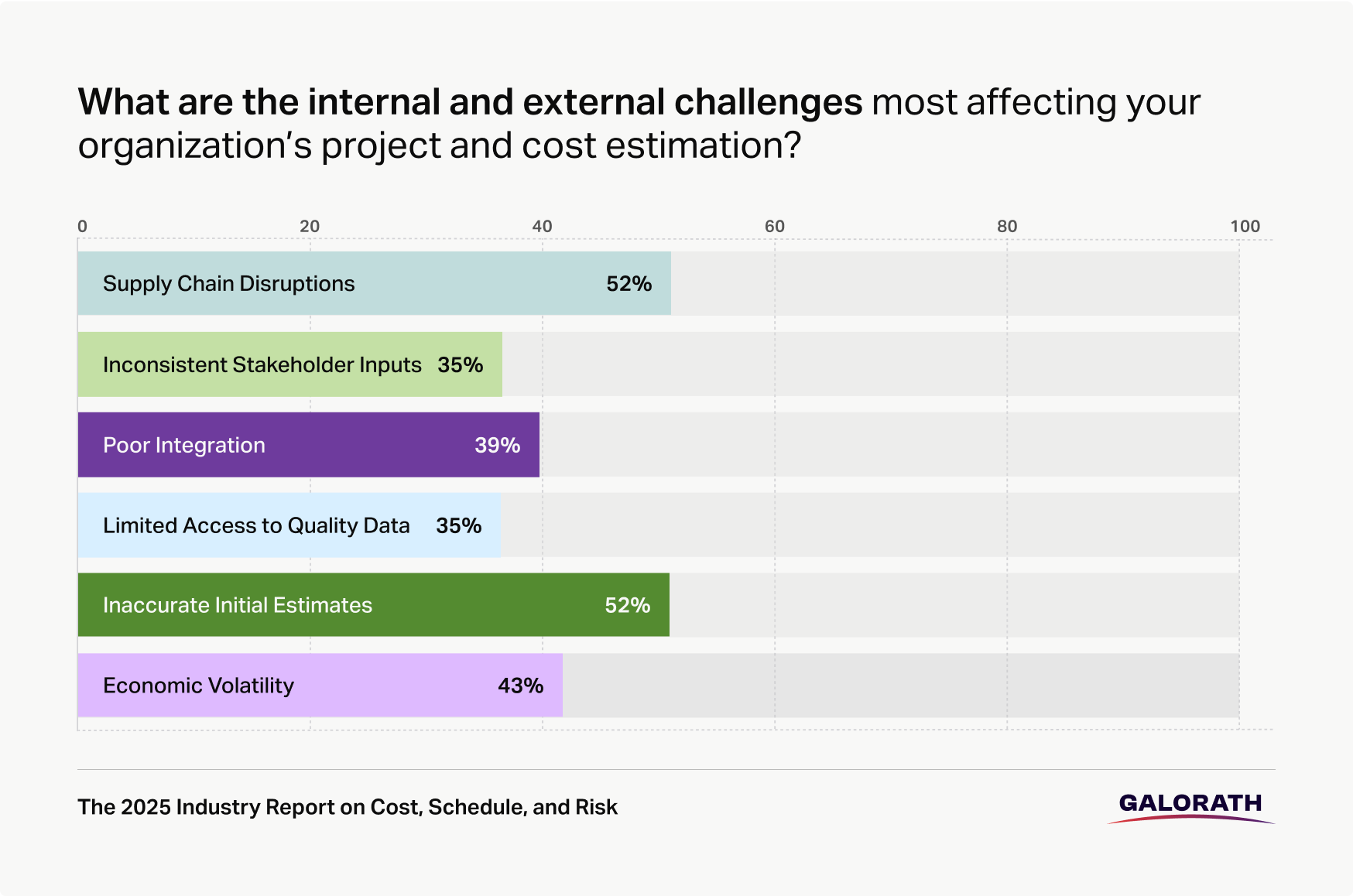

Manufacturers are running into the same wall again and again: rising costs, slipping timelines, and tools that no longer do the job. While production teams move faster and customer demands grow louder, cost estimation is stuck in the past.

This report is built on a foundation of carefully screened participants and thoroughly vetted data. Every response was subject to rigorous quality checks to ensure both reliability and relevance. The result is a set of insights that support critical business decisions with accuracy, authority, and practical value. The numbers show widespread frustration, low confidence, and growing urgency to modernize. Spreadsheets are still the default. Automation is rare. Many teams are being asked to hit targets without real-time data, integrated tools, or adequate training.

Expectations are rising faster than most manufacturers can keep up. Those that invest in better systems, stronger data, and internal expertise will be positioned to lead. Those that don’t will continue to lose ground.

Galorath’s 2025 Industry Report on Cost, Schedule, and Risk was conducted in partnership with NewtonX, an independent research firm specializing in verified professional insights.

The survey gathered perspectives from 180 senior and mid-level professionals across industries where cost, schedule, and risk estimation are mission critical. Participants were recruited through a custom process and verified through multi-layer identity authentication to ensure subject matter expertise. Each respondent completed the survey via a unique, single-use link with strict quality controls, fraud detection, and response validation protocols. This approach provides a reliable, third-party–verified view of how organizations are approaching project planning in today’s volatile environment.

Manufacturing has always demanded speed, accuracy, and adaptability. But in 2025, those demands are rising faster than most teams can keep up. Material prices fluctuate without warning, supply chains shift mid-cycle, and customers expect transparency in cost and delivery. Despite these conditions, many cost estimation processes rely on spreadsheets, delayed inputs, and informal workarounds, leaving teams vulnerable to change.

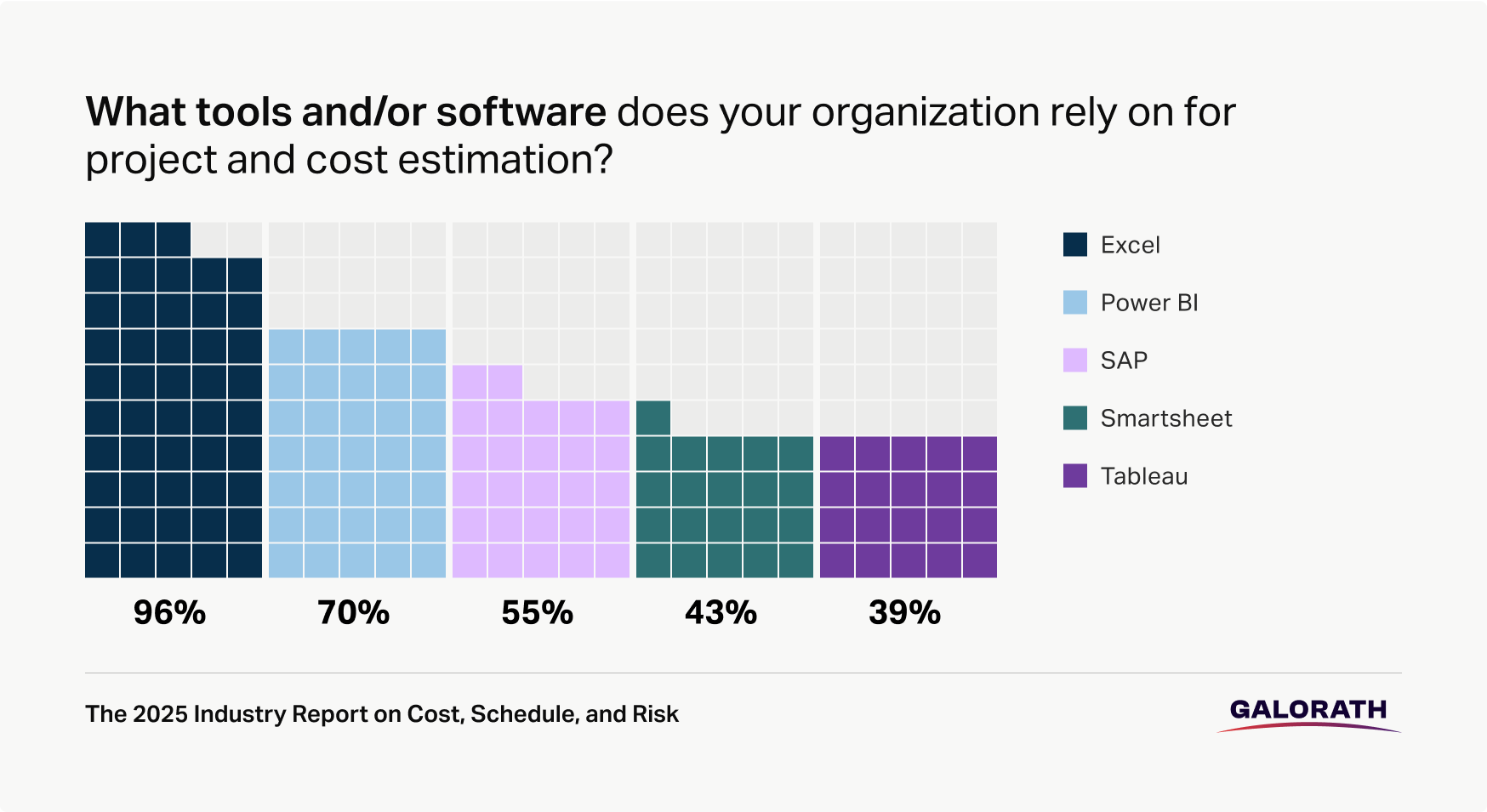

The data is clear: 96% of manufacturers still rely on Excel to manage cost estimation. Only 4% have automated more than three-quarters of their process. The result is avoidable errors, manual rework, and slower decisions. Estimation is no longer just a financial exercise, it directly impacts delivery timelines, profit margins, and customer satisfaction. To stay competitive, manufacturers need to modernize.