Mastering Cost Risk with the CRED Model: A New Approach to Managing Uncertainty

AI-powered DFM for smarter manufacturing decisions

Manufacturing success depends on design choices made early. Galorath’s SEER® platform and SEERai™ help teams balance innovation with cost, labor, and schedule. With DFM AI, you can test alternatives, optimize manufacturability, and deliver products faster with fewer surprises.

AI in design for manufacturing

AI for computational design and manufacturing brings visibility and control to early trade-offs.

Design choices often lock in cost, effort, and risk before production begins. Without transparency, teams face expensive redesigns and missed targets. SEER and SEERai enable AI-driven design optimization for manufacturability. Engineers and planners can evaluate materials, processes, and configurations early, seeing how decisions impact feasibility, cost, and schedule. Unlike black-box systems, our platform delivers DFM AI with explainable models and visible drivers, so every recommendation is traceable and defensible.

Design for manufacturing clarity

Design optimization for manufacturability reduces rework and accelerates delivery.

Design for manufacturing (DFM) is where early decisions set the course for cost, labor, and quality. Without visibility, teams risk expensive redesigns and late-stage changes. Galorath’s SEER platform and SEERai bring DFM AI into the process, turning assumptions into transparent inputs and outputs. AI for computational design and manufacturing allows engineers to explore materials, processes, and trade-offs with confidence. The result is AI-driven design optimization for manufacturability that helps teams catch issues early, balance performance and cost, and move forward with greater certainty.

DFM benefits in practice

Why design for manufacturing accuracy saves time and cost

DFM AI gives teams the insight to design smarter, avoid costly rework, and align across functions.

Early feasibility checks

Test manufacturability early to avoid downstream changes and late-stage redesigns.

Design-to-cost clarity

Connect design options to cost and labor impacts so teams make trade-offs with confidence.

Process optimization

AI for computational design and manufacturing identifies efficient production paths.

Fewer surprises later

Catch manufacturability issues in design, not during production, to reduce risk.

Cross-team alignment

Engineers, sourcing, and finance share one model of manufacturability and cost.

Audit-ready outputs

Each optimization is backed by visible inputs and rationale that withstand review.

Trusted in design-to-cost programs

Manufacturers rely on Galorath for transparent, explainable design-for-manufacturing analysis.

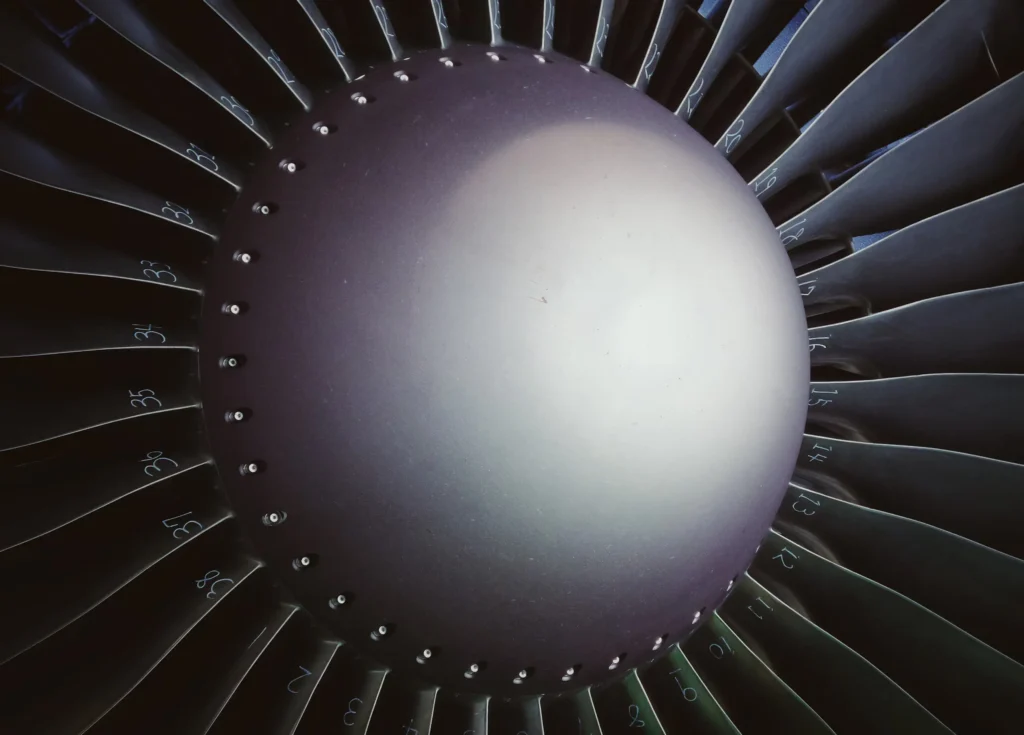

Across aerospace, automotive, and industrial sectors, Galorath supports design teams that need to bring products to market faster without overruns. SEER and SEERai combine proven models with AI-driven design optimization for manufacturability, showing the real impact of material choices, configurations, and processes. This platform is more than DFM AI; it is a system of explainable analysis that connects cost, labor, and schedule. Manufacturers trust Galorath when getting design right the first time is critical to quality, margins, and delivery.

Design optimization explained

How AI transforms design for manufacturing across industries

DFM is where innovation meets feasibility. Galorath connects engineering, sourcing, and finance through AI for computational design and manufacturing, giving teams a shared, defensible view.

Software

Apply DFM AI to PCB layouts, packaging, and integration to see cost and manufacturability issues before production begins, saving time and reducing rework.

Hardware

AI-driven design optimization for manufacturability helps evaluate parts, processes, and materials early. Teams can compare options and avoid costly redesigns during fabrication.

Systems Engineering

Large systems require cross-discipline visibility. Galorath links design trade-offs to cost, schedule, and labor, giving decision-makers forecasts they can defend at every stage.

Proven results from Galorath in action

See how manufacturers achieved savings with AI-driven design optimization for manufacturability.

Explore our Case Studies

See how Lockheed Martin accelerated manufacturability and cost estimating

Lockheed Martin used Galorath’s SEER during cost estimating for airframe components. By modeling assemblies with real cost drivers instead of manual lookups, they reduced estimate time from days to hours, even for complex subsystems, while improving model transparency.

Read more →“The SEER tools are equally strong at estimating both software and hardware costs. When you use a parametric model like SEER, you reduce uncertainty by deconstructing the project into smaller, well-defined components, the cost estimate of which can be more readily critiqued by the technical and program management staff. SEER is easy [to use] and intuitive.”

Frequently Asked Questions (FAQ)

What is design for manufacturing (DFM)?

DFM evaluates how design decisions affect cost, labor, and production. Galorath enhances this process with DFM AI, making manufacturability analysis transparent and faster.

How does AI improve DFM?

AI for computational design and manufacturing accelerates input gathering, scenario modeling, and optimization. With SEER and SEERai, teams gain clear, explainable outputs that reduce redesigns.

What makes Galorath different in DFM?

Many tools provide black-box results. Galorath combines proven models with AI-driven design optimization for manufacturability, delivering transparent, defensible recommendations.

Take the next step toward AI-powered DFM and smarter manufacturing outcomes

See how SEER and SEERai bring transparency to DFM AI, reducing rework and improving delivery confidence. Schedule a consultation to learn how AI for computational design and manufacturing helps.

Trusted by leaders in the industry: