Mastering Cost Risk with the CRED Model: A New Approach to Managing Uncertainty

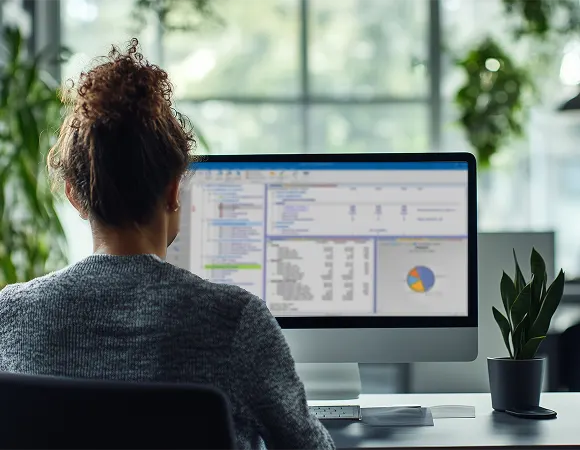

Design for Manufacturing Software for Smarter Engineering Decisions

Galorath’s SEER® platform helps manufacturers reduce rework, optimize cost early, and streamline production planning. SEERai™, the platform’s AI layer, powers Design for Manufacturing workflows that connect engineering, cost, and sourcing to bring transparency and control to every product decision.

Cut Rework, Stay on Budget

Manufacturers reduce late-stage changes by integrating cost logic during design

SEER and SEERai surface cost drivers that impact manufacturability, such as material choices and assembly processes, so teams can resolve issues before release. By analyzing labor impact, part count, and waste factors within SEER’s trusted models, users get realistic feedback early. AI agents help simulate design alternatives and estimate their effects on downstream costs. The result is fewer engineering change orders, stronger supplier alignment, and faster design-to-delivery cycles.

Align Cost with Manufacturing Goals

Connect design, cost, and sourcing to improve manufacturability and reduce production delays

With Galorath’s SEER platform, manufacturers can evaluate cost and complexity across design options before production begins. The platform identifies trade-offs related to materials, part count, and labor early in the process, allowing teams to make informed decisions that support both performance and manufacturability. Integrated guidance and AI agents ensure design, cost, and procurement teams work from a shared source of truth. This alignment reduces late-stage surprises and shortens the path from prototype to production.

Drive Early Alignment Across Teams

Why Design for Manufacturing Must Start with Estimation Insight

Improve collaboration between engineering, cost, and production teams with SEERai’s intelligent DFM support.

Estimate Part Complexity Early

Use SEERai to model part count and design impact on cost before sending designs to procurement or suppliers.

Reduce Material Waste and Rework

Identify material inefficiencies and cost drivers during early-stage planning to avoid late-stage change orders.

Unify Design and Cost Objectives

Align technical feasibility with budget targets to reduce trade-offs and accelerate design-to-production cycles.

Streamline Manufacturing Decisions

Test different manufacturing scenarios using real assumptions and trusted SEER models to choose the best path forward.

Support Cost-Aware Engineering

Help engineers make smarter choices with visibility into how design decisions affect cost, labor, and delivery speed.

Accelerate Supplier Engagement

Share clear, cost-informed requirements with suppliers to reduce back-and-forth and speed up sourcing timelines.

Build Confidently with Cost Insight

SEER brings manufacturing awareness into design, improving outcomes across teams and timelines

Galorath’s SEER platform empowers teams to evaluate manufacturability during design, not after. With built-in cost logic, real-world benchmarks, and AI-supported guidance, teams can make design decisions that reflect production realities. Whether evaluating part geometry, assembly methods, or labor constraints, SEERai helps teams model true downstream impact. This early visibility reduces friction between design and sourcing, prevents late-stage rework, and keeps programs on schedule. Design choices align with cost, feasibility, and delivery goals.

Explore Estimation Across Domains

Bring DFM Insights to Software, Hardware, and Systems Teams

Design for Manufacturing is not limited to mechanical parts. The SEER platform helps teams across software, hardware, and systems engineering model downstream impacts earlier in the design process.

Software Development

SEERai enables software teams to evaluate how design choices affect integration, delivery, and cost. Model effort by component and optimize early for reuse and team structure.

Hardware Development

Hardware teams use SEERai to assess part complexity, process requirements, and material efficiency. Early visibility into cost and manufacturability prevents late-stage surprises.

Systems Engineering

SEERai connects cross-functional design inputs with cost, schedule, and risk models. Systems engineers can test trade-offs and align stakeholders before design is finalized.

Validate Manufacturability Before Production

Galorath’s platform brings early-stage manufacturability analysis into design workflows. Teams evaluate production feasibility, complexity and cost before committing to tooling.

Explore our Case Studies

Composites Affordability Initiative Cuts Production Costs

A composites program used Galorath’s platform to assess manufacturing complexity early. The effort revealed cost drivers and enabled design adjustments that lowered production costs.

Read more →“The SEER tools are equally strong at estimating both software and hardware costs. When you use a parametric model like SEER, you reduce uncertainty by deconstructing the project into smaller, well-defined components, the cost estimate of which can be more readily critiqued by the technical and program management staff. SEER is easy [to use] and intuitive.”

Frequently Asked Questions (FAQ)

Can SEER support both high-level and detailed DFM estimates?

Yes. SEER and SEERai allow teams to begin with early-phase, high-level cost insights or drill down into detailed manufacturing estimates. Users can model part complexity, process choices, and labor inputs with traceable logic that evolves as the design matures.

How does SEER improve design-to-production alignment?

SEER and SEERai connect design decisions to real-world manufacturing outcomes by identifying cost drivers early. Teams can evaluate trade-offs in materials, part count, and assembly steps, helping them avoid rework and accelerate time to production.

What makes SEER and SEERai different from other DFM tools?

SEER and SEERai integrate AI guidance with SEER’s trusted parametric models, so design, engineering, and sourcing teams work from the same data. It supports natural-language interaction and scenario testing, making cost-aware DFM accessible and accurate.

Connect cost, design, and manufacturability. Take the next step.

Ready to bring cost awareness into your design process? Request a consultation to see how SEER helps manufacturers reduce rework and accelerate time to production.

Trusted by leaders in the industry: